PARADOXA INSIGHTS CONSTRUCTION & SHAPE

|

ICF WOLDCHAMPION MASTER 50 PETER WEIDERT in full flight on the PARADOXA 22

|

|

|

|

|

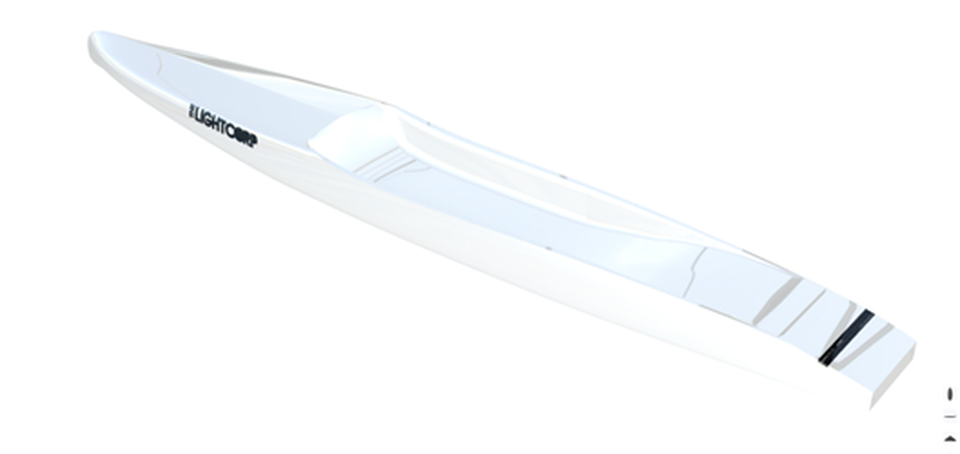

14´x 21" / Volume: 267L / wetted surface*: 18.367 cm2 / optimized rockerline: 55 - 77.5kg

14´x 22" / Volume: 278L / wetted surface*: 19.256 cm2 / optimized rockerline: 70.0 - 85.0kg

14´x 23" / Volume: 296L / wetted surface*: 20.132 cm2 / optimized rockerline: 77.5 - 95.0kg

14´ x 24.5" / Volume: 316L / wetted surface*: 21.900 cm2 / optimized rockerline: 88.5 - 112.5kg

new release PARADOXA 24.5 - now ready to order

* all shapes are cad designed and have optimized rockerlines based on assumed paddler weight and board dimensions. Waterline is exactly at the bottom tail edge with full running length to the tip of the nose. This new shape is optimized for the best flatwater performance but can handle choppy conditions with incredible stability.

SRP € 4.600

new radical lowcenter deckstance - under waterline - combined with drainage valve system

new tail shape optimizing stability and easyness of turning - wider tailblock with tapered thickness

hard tail edges to create the least possible interference releasing the water

optimized sleek v-round nose shape to reduce drag

new s-style deck contour to reduce water entry at buoy turns

For me it is the most sexy supraceboard in the world. It's technology is a world's first in sup construction. It's versatility is huge and as a flatware design it can handle rough conditions. Simply speaking it's very stable and super fast. How comes that ? Usually boards are either stable or fast - that's why it it is the PARADOXA..

Take in mind you paddle as fast as with a 23" but feel comfortable like on a 25" wide board.

In comparison to the Mantra 2.0 we arranged a wider tail and gave the front part in the first 50cm a more narrow outline. The magic rocker line is based on the super fast Mantra 23.2 with slight adjustments to meet the targeted paddler weight. The center bottom has a subtle concave with edges gradually running from round to really sharp in the tail. This creates more 1st stability without sacrificing wetted surface which creates drag. The rockerline features a flat center line and straight low rocker in the last 1/3rd which makes the board a wash riding giant even in the 2nd and 3rd wave and will save energy when needed. This shape handles wind waves and chop with the all new exaggerated "Vround" front bottom and you can easily overtake small waves cutting through instead of paddling above. The dugout stance is below waterline and the most radical design available in serial production. This is possible due to the function of our drainage valve system which let´s water out but not in. This stance position creates additional stability and better leverage and power to your blade.

The sidewalls are high to prevent water entry in rougher conditions and slim enough to offer huge standing options.

The sideline is heavily tapered in the back to prevent water entry while turning.

Overall flex is super stiff, way far from what you know from premium eps core carbon boards. Our new UD - AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY in hollow construction has 4 layers of unidirectional carbon around the center high density foam layer. The curing process is accurate managed under pressure and heat in AUTOCLAVE technology.. Every stroke will push you forward and you will not loose energy in flex.

The carbon outer shell is that tight that you do not need a gelcoat or 2k lacquer for protection. So we decided you can choose the even more lightweight naked version or some variety in design and colors.

The new PREPREG UD technology is not only superior in speed but also the most ECO FRIENDLY way to manufacture - no eps core, no wet lamination and excess resin.

Cheers Gerd

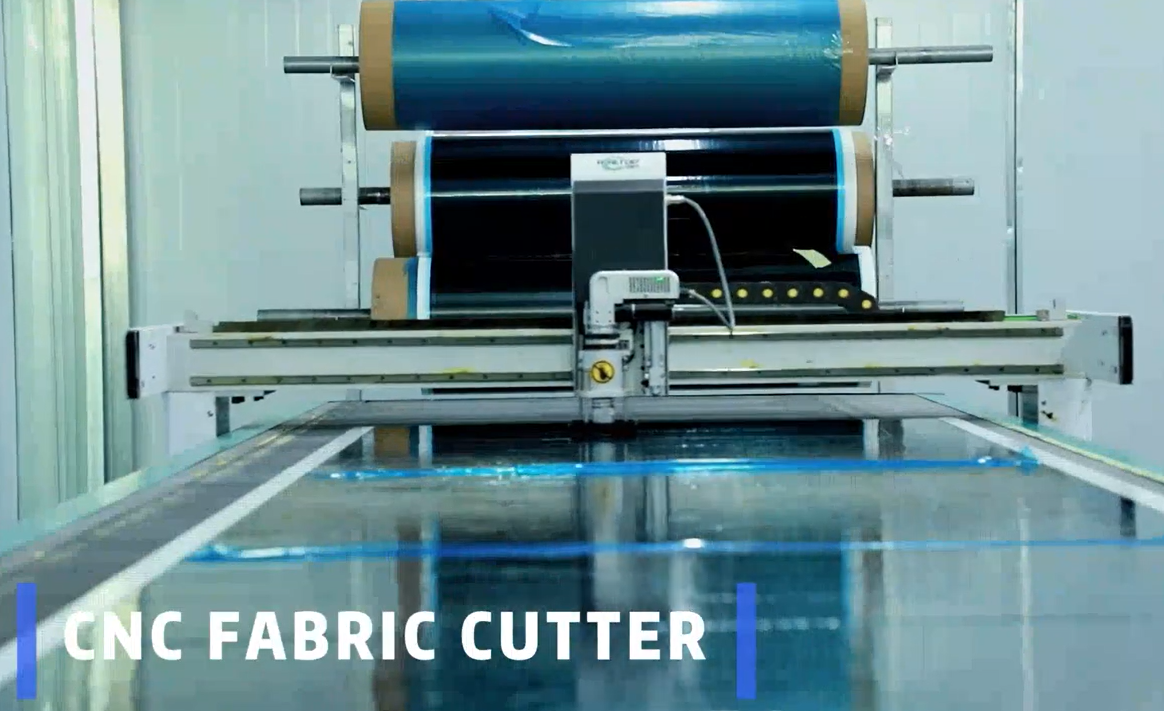

AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY - eco friendly

While paddling each stroke energy is transmitted to forward momentum .

|

Unidirectional Prepreg carbon fiber fabric is non-woven and features all fibers running in a single, parallel direction. It is pre impregnated with resin in a computer controlled process. There are no gaps between fibers, and each fiber is impreganted with exactly the amount of resin that is necessary for perfect bonding in the lamination process. There is no cross-section weave that divides the fiber strength in half with another direction. This allows for the concentrated density of fibers that provide maximum longitudinal strength.

|

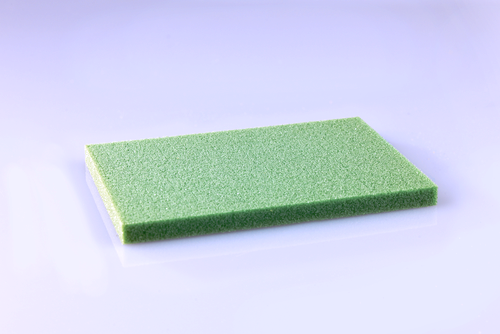

Closed cell high density PVC foam is used for the core between the carbon layers. It provides stiffness and durability in a lightweight sandwich structure. We use different thickness layups to create extra durability in strategic areas of the board hull.

|

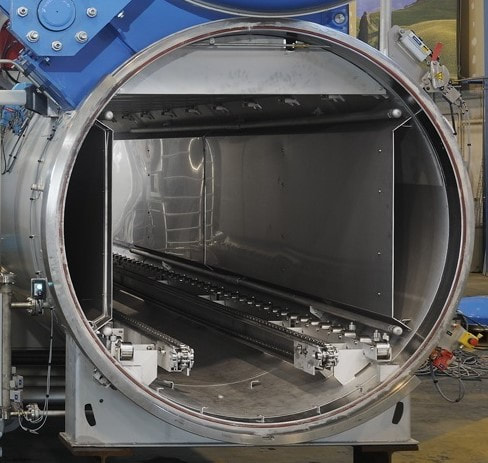

The composite curing AUTOCLAVE lamination process is the key factor for better durability, weight advantage and longevity. Autoclave enables us to control the cure time, temperature, pressure and vacuum accurately. The bonding between the unidirectional prepreg carbon fibers, pvc sandwich foam is leading the uncomparable strength ratio. It is aso less harmfull for the envionment and working staff as we do not need to operate in the classic wet lamination process.

|

The boards are finished with high quality 2K Marine paint providing 100% UV protection and superior scratch and chemical resistance. Our finish is usually shiny but we offer matt finish as well.

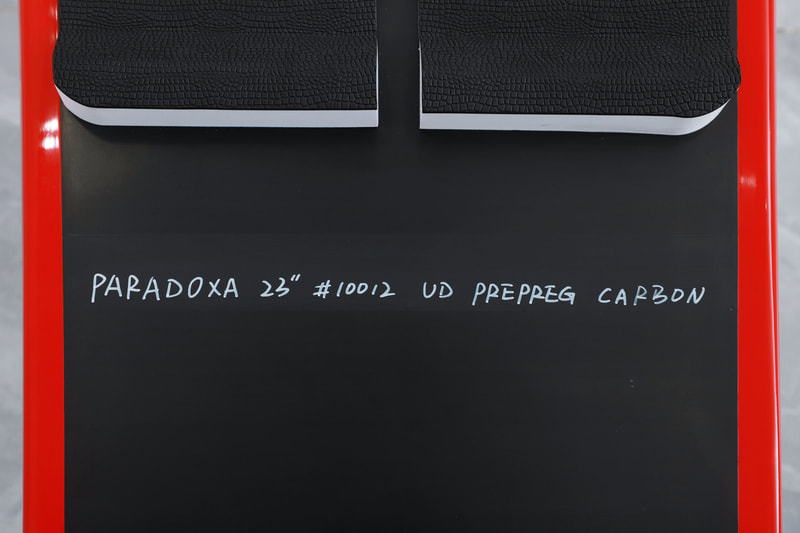

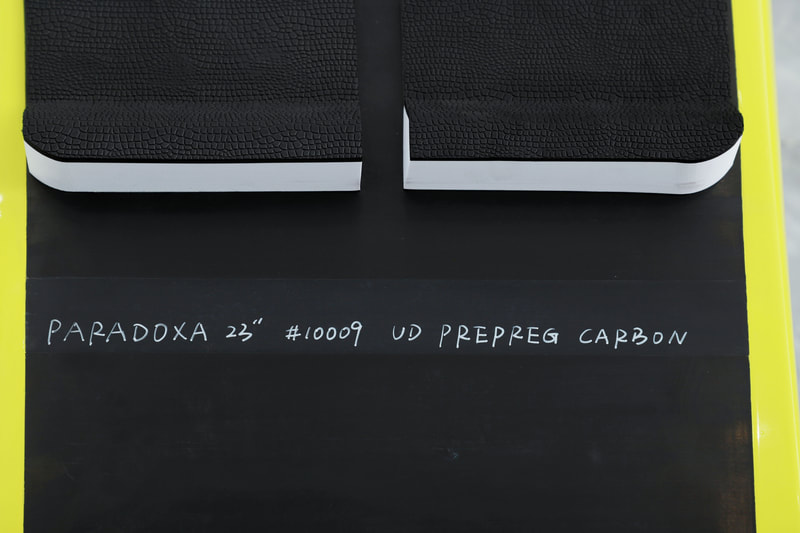

There is a clear design stripe in the tail of the boards with the visible UD construction and handwritten serial number and dimension. We offer multiple design proposals. |

LIGHT PARADOXA 14´ UD PREPREG CARBON HOLLOW CONSTRUCTION BLUE WHITE - freight free shipment delivery time 6-8 weeks

LIGHTBOARDCORP® PARADOXA UD PREPREG CARBON HOLLOW CONSTRUCTION

14´x 21" / Volume: 270L / wetted surface*: 19.600 cm2 / optimized rockerline: 62.5 - 77.5kg

14´x 22" / Volume: 278L / wetted surface*: 19.256 cm2 / optimized rockerline: 70.0 - 85.0kg

14´x 23" / Volume: 296L / wetted surface*: 20.100 cm2 / optimized rockerline: 77.5 - 95.0kg

14´ x 24.5" / Volume: 316L / wetted surface*: 21.900 cm2 / optimized rockerline: 88.5 - 112.5kg

painted glossfinish 10kg / naked carbon 9kg

Simply speaking it's very stable and super fast. Usually boards are either stable or fast - that's why it it is the PARADOXA..

Take in mind you paddle as fast as with a 23" but feel comfortable like on a 25" wide board.

In comparison to the Mantra 2.0 we arranged a wider tail and gave the front part in the first 50cm a more narrow outline. The magic rocker line is based on the super fast Mantra 23.2 with slight adjustments to meet the targeted paddler weight.The center bottom has a subtle concave with edges gradually running from round to really sharp in the tail. This creates more 1st stability without sacrificing wetted surface which creates drag. The rockerline features a flat center line and straight low rocker in the last 1/3rd which makes the board a wash riding giant even in the 2nd and 3rd wave and will save energy when needed. This shape handles wind waves and chop with the all new exaggerated "Vround" front bottom and you can easily overtake small waves cutting through instead of paddling above. The dugout stance is below waterline and the most radical design available in serial production. This is possible due to the function of our drainage valve system which let´s water out but not in. This stance position creates additional stability and better leverage and power to your blade.

The sidewalls are high to prevent water entry in rougher conditions and slim enough to offer huge standing options.

The sideline is heavily tapered in the back to prevent water entry while turning.

Overall flex is super stiff, way far from what you know from premium eps core carbon boards. Our new UD - AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY in hollow construction has 4 layers of unidirectional carbon around the center high density foam layer. The curing process is accurate managed under pressure and heat in AUTOCLAVE technology.. Every stroke will push you forward and you will not loose energy in flex.

The carbon outer shell is that tight that you do not need a gelcoat or 2k lacquer for protection. So we decided you can choose the even more lightweight naked version or some variety in design and colors.

The new PREPREG UD technology is not only superior in speed but also the most ECO FRIENDLY way to manufacture - no eps core, no wet lamination and excess resin.

Cheers Gerd

AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY - eco friendly

This technology is based on premium production standards developed for aerospace and formula racing cars. 4 layers of epoxy resin impreganted unidirectional carbon fiber with a closed cell high density pvc foam in the center are layed up in the mold . There is no wet lamination necessary as the curing happens in autoclave technology using 4-5 times atmospheric pressure + heat which melts the resin and bonds all layers far more accurate compared to wet lamination process. Our new UD PREPREG technology is far more eco friendly than conventional build sup raceboards. No styrofoam core, less harmfull lamination process, no excess epoxy resin and guaranteed precision to bond each fiber leads to longevity, precise shapes and higher performance.

While paddling each stroke energy is transmitted to forward momentum .

CUSTOMISATION

please check our website

DELIVERY TIME

We calculate with 6-8 weeks delivery time. In urgent needs we usually carry a choice of designs and colors on our stock for immediate delivery.

MAINTENANCE

The advantage of composites is that they don´t require much maintenance; of course there are some crucial rules to extend the lifetime of your race board:

- do not put it in the sun for long periods

- do not tight it too strongly on the rack and place it upside down

- never store or transport it inside the cover if the board is not well dry

- and treat it like a baby

USAGE

Raceboards should be used only by trained persons or under supervision

WARRANTY

we offer a 2 year warranty but do not take responsibility for:

- misuse

- damage caused by transport

- repairs made by unauthorized personnel

This warranty covers any fabrication defects on the board or parts, as well as changes in the material characteristics.

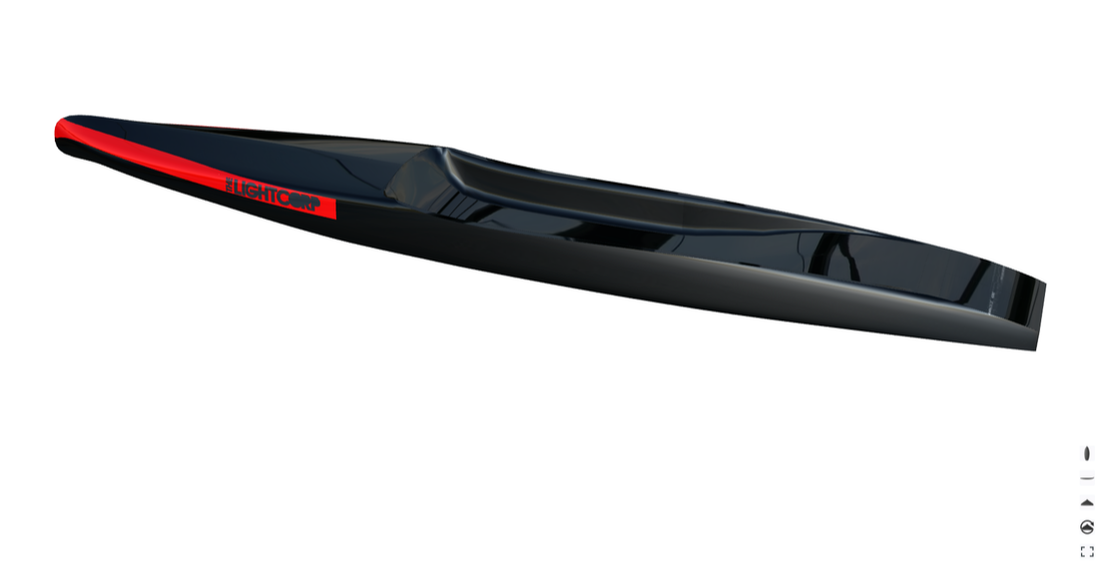

LIGHT PARADOXA 14´ UD PREPREG CARBON HOLLOW CONSTRUCTION NAKED MATT BLACK RED- freight free shipment delivery time 6-8 weeks

LIGHTBOARDCORP® PARADOXA UD PREPREG CARBON HOLLOW CONSTRUCTION

14´x 21" / Volume: 270L / wetted surface*: 19.600 cm2 / optimized rockerline: 62.5 - 77.5kg

14´x 22" / Volume: 278L / wetted surface*: 19.256 cm2 / optimized rockerline: 70.0 - 85.0kg

14´x 23" / Volume: 296L / wetted surface*: 20.100 cm2 / optimized rockerline: 77.5 - 95.0kg

14´ x 25" / Volume: 322L / wetted surface*: 21.900 cm2 / optimized rockerline: 88.5 - 112.5kg

painted glossfinish 10kg / naked carbon 9kg

Simply speaking it's very stable and super fast. Usually boards are either stable or fast - that's why it it is the PARADOXA..

Take in mind you paddle as fast as with a 23" but feel comfortable like on a 25" wide board.

In comparison to the Mantra 2.0 we arranged a wider tail and gave the front part in the first 50cm a more narrow outline. The magic rocker line is based on the super fast Mantra 23.2 with slight adjustments to meet the targeted paddler weight.The center bottom has a subtle concave with edges gradually running from round to really sharp in the tail. This creates more 1st stability without sacrificing wetted surface which creates drag. The rockerline features a flat center line and straight low rocker in the last 1/3rd which makes the board a wash riding giant even in the 2nd and 3rd wave and will save energy when needed. This shape handles wind waves and chop with the all new exaggerated "Vround" front bottom and you can easily overtake small waves cutting through instead of paddling above. The dugout stance is below waterline and the most radical design available in serial production. This is possible due to the function of our drainage valve system which let´s water out but not in. This stance position creates additional stability and better leverage and power to your blade.

The sidewalls are high to prevent water entry in rougher conditions and slim enough to offer huge standing options.

The sideline is heavily tapered in the back to prevent water entry while turning.

Overall flex is super stiff, way far from what you know from premium eps core carbon boards. Our new UD - AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY in hollow construction has 4 layers of unidirectional carbon around the center high density foam layer. The curing process is accurate managed under pressure and heat in AUTOCLAVE technology.. Every stroke will push you forward and you will not loose energy in flex.

The carbon outer shell is that tight that you do not need a gelcoat or 2k lacquer for protection. So we decided you can choose the even more lightweight naked version or some variety in design and colors.

The new PREPREG UD technology is not only superior in speed but also the most ECO FRIENDLY way to manufacture - no eps core, no wet lamination and excess resin.

Cheers GerdAUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY - eco friendly

This technology is based on premium production standards developed for aerospace and formula racing cars. 4 layers of epoxy resin impreganted unidirectional carbon fiber with a closed cell high density pvc foam in the center are layed up in the mold . There is no wet lamination necessary as the curing happens in autoclave technology using 4-5 times atmospheric pressure + heat which melts the resin and bonds all layers far more accurate compared to wet lamination process. Our new UD PREPREG technology is far more eco friendly than conventional build sup raceboards. No styrofoam core, less harmfull lamination process, no excess epoxy resin and guaranteed precision to bond each fiber leads to longevity, precise shapes and higher performance.

While paddling each stroke energy is transmitted to forward momentum .

CUSTOMISATION

please check our website

DELIVERY TIME

We calculate with 6-8 weeks delivery time. In urgent needs we usually carry a choice of designs and colors on our stock for immediate delivery.

MAINTENANCE

The advantage of composites is that they don´t require much maintenance; of course there are some crucial rules to extend the lifetime of your race board:

- do not put it in the sun for long periods

- do not tight it too strongly on the rack and place it upside down

- never store or transport it inside the cover if the board is not well dry

- and treat it like a baby

USAGE

Raceboards should be used only by trained persons or under supervision

WARRANTY

we offer a 2 year warranty but do not take responsibility for:

- misuse

- damage caused by transport

- repairs made by unauthorized personnel

This warranty covers any fabrication defects on the board or parts, as well as changes in the material characteristics.

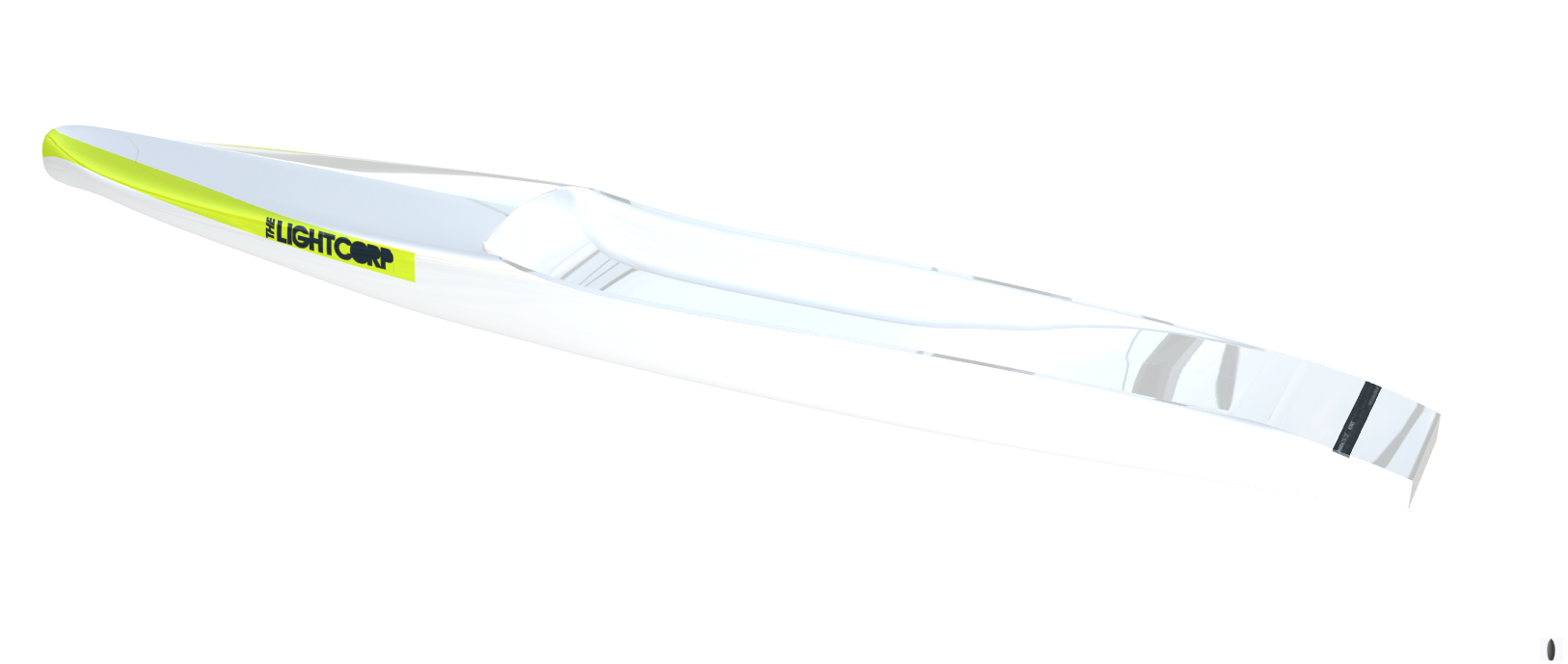

LIGHT PARADOXA 14´ UD PREPREG CARBON HOLLOW CONSTRUCTION WHITE - freight free shipment delivery time 6-8 weeks

LIGHTBOARDCORP® PARADOXA UD PREPREG CARBON HOLLOW CONSTRUCTION

14´x 21" / Volume: 270L / wetted surface*: 19.600 cm2 / optimized rockerline: 62.5 - 77.5kg

14´x 22" / Volume: 278L / wetted surface*: 19.256 cm2 / optimized rockerline: 70.0 - 85.0kg

14´x 23" / Volume: 296L / wetted surface*: 20.100 cm2 / optimized rockerline: 77.5 - 95.0kg

14´ x 24.5" / Volume: 316L / wetted surface*: 21.900 cm2 / optimized rockerline: 88.5 - 112.5kg

painted glossfinish 10kg / naked carbon 9kg

Simply speaking it's very stable and super fast. Usually boards are either stable or fast - that's why it it is the PARADOXA..

Take in mind you paddle as fast as with a 23" but feel comfortable like on a 25" wide board.

In comparison to the Mantra 2.0 we arranged a wider tail and gave the front part in the first 50cm a more narrow outline. The magic rocker line is based on the super fast Mantra 23.2 with slight adjustments to meet the targeted paddler weight.The center bottom has a subtle concave with edges gradually running from round to really sharp in the tail. This creates more 1st stability without sacrificing wetted surface which creates drag. The rockerline features a flat center line and straight low rocker in the last 1/3rd which makes the board a wash riding giant even in the 2nd and 3rd wave and will save energy when needed. This shape handles wind waves and chop with the all new exaggerated "Vround" front bottom and you can easily overtake small waves cutting through instead of paddling above. The dugout stance is below waterline and the most radical design available in serial production. This is possible due to the function of our drainage valve system which let´s water out but not in. This stance position creates additional stability and better leverage and power to your blade.

The sidewalls are high to prevent water entry in rougher conditions and slim enough to offer huge standing options.

The sideline is heavily tapered in the back to prevent water entry while turning.

Overall flex is super stiff, way far from what you know from premium eps core carbon boards. Our new UD - AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY in hollow construction has 4 layers of unidirectional carbon around the center high density foam layer. The curing process is accurate managed under pressure and heat in AUTOCLAVE technology.. Every stroke will push you forward and you will not loose energy in flex.

The carbon outer shell is that tight that you do not need a gelcoat or 2k lacquer for protection. So we decided you can choose the even more lightweight naked version or some variety in design and colors.

The new PREPREG UD technology is not only superior in speed but also the most ECO FRIENDLY way to manufacture - no eps core, no wet lamination and excess resin.

Cheers Gerd

AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY - eco friendly

This technology is based on premium production standards developed for aerospace and formula racing cars. 4 layers of epoxy resin impreganted unidirectional carbon fiber with a closed cell high density pvc foam in the center are layed up in the mold . There is no wet lamination necessary as the curing happens in autoclave technology using 4-5 times atmospheric pressure + heat which melts the resin and bonds all layers far more accurate compared to wet lamination process. Our new UD PREPREG technology is far more eco friendly than conventional build sup raceboards. No styrofoam core, less harmfull lamination process, no excess epoxy resin and guaranteed precision to bond each fiber leads to longevity, precise shapes and higher performance.

While paddling each stroke energy is transmitted to forward momentum .

CUSTOMISATION

please check our website

DELIVERY TIME

We calculate with 6-8 weeks delivery time. In urgent needs we usually carry a choice of designs and colors on our stock for immediate delivery.

MAINTENANCE

The advantage of composites is that they don´t require much maintenance; of course there are some crucial rules to extend the lifetime of your race board:

- do not put it in the sun for long periods

- do not tight it too strongly on the rack and place it upside down

- never store or transport it inside the cover if the board is not well dry

- and treat it like a baby

USAGE

Raceboards should be used only by trained persons or under supervision

WARRANTY

we offer a 2 year warranty but do not take responsibility for:

- misuse

- damage caused by transport

- repairs made by unauthorized personnel

This warranty covers any fabrication defects on the board or parts, as well as changes in the material characteristics.

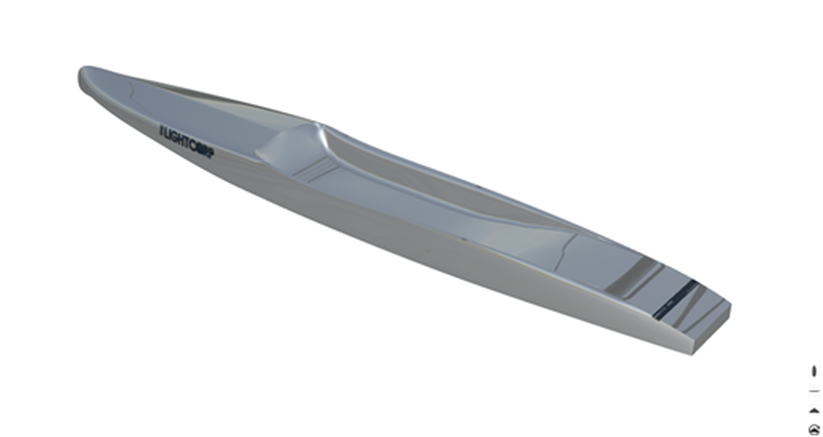

LIGHT PARADOXA 14´ UD PREPREG CARBON HOLLOW CONSTRUCTION BLACK NAKED - RED - freight free shipment delivery time 6-8 weeks

LIGHTBOARDCORP® PARADOXA UD PREPREG CARBON HOLLOW CONSTRUCTION

14´x 21" / Volume: 270L / wetted surface*: 19.600 cm2 / optimized rockerline: 62.5 - 77.5kg

14´x 22" / Volume: 278L / wetted surface*: 19.256 cm2 / optimized rockerline: 70.0 - 85.0kg

14´x 23" / Volume: 296L / wetted surface*: 20.100 cm2 / optimized rockerline: 77.5 - 95.0kg

14´ x 25" / Volume: 322L / wetted surface*: 21.900 cm2 / optimized rockerline: 88.5 - 112.5kg

painted glossfinish 10kg / naked carbon 9kg

Simply speaking it's very stable and super fast. Usually boards are either stable or fast - that's why it it is the PARADOXA..

Take in mind you paddle as fast as with a 23" but feel comfortable like on a 25" wide board.

In comparison to the Mantra 2.0 we arranged a wider tail and gave the front part in the first 50cm a more narrow outline. The magic rocker line is based on the super fast Mantra 23.2 with slight adjustments to meet the targeted paddler weight.The center bottom has a subtle concave with edges gradually running from round to really sharp in the tail. This creates more 1st stability without sacrificing wetted surface which creates drag. The rockerline features a flat center line and straight low rocker in the last 1/3rd which makes the board a wash riding giant even in the 2nd and 3rd wave and will save energy when needed. This shape handles wind waves and chop with the all new exaggerated "Vround" front bottom and you can easily overtake small waves cutting through instead of paddling above. The dugout stance is below waterline and the most radical design available in serial production. This is possible due to the function of our drainage valve system which let´s water out but not in. This stance position creates additional stability and better leverage and power to your blade.

The sidewalls are high to prevent water entry in rougher conditions and slim enough to offer huge standing options.

The sideline is heavily tapered in the back to prevent water entry while turning.

Overall flex is super stiff, way far from what you know from premium eps core carbon boards. Our new UD - AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY in hollow construction has 4 layers of unidirectional carbon around the center high density foam layer. The curing process is accurate managed under pressure and heat in AUTOCLAVE technology.. Every stroke will push you forward and you will not loose energy in flex.

The carbon outer shell is that tight that you do not need a gelcoat or 2k lacquer for protection. So we decided you can choose the even more lightweight naked version or some variety in design and colors.

The new PREPREG UD technology is not only superior in speed but also the most ECO FRIENDLY way to manufacture - no eps core, no wet lamination and excess resin.

Cheers Gerd

AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY - eco friendly

This technology is based on premium production standards developed for aerospace and formula racing cars. 4 layers of epoxy resin impreganted unidirectional carbon fiber with a closed cell high density pvc foam in the center are layed up in the mold . There is no wet lamination necessary as the curing happens in autoclave technology using 4-5 times atmospheric pressure + heat which melts the resin and bonds all layers far more accurate compared to wet lamination process. Our new UD PREPREG technology is far more eco friendly than conventional build sup raceboards. No styrofoam core, less harmfull lamination process, no excess epoxy resin and guaranteed precision to bond each fiber leads to longevity, precise shapes and higher performance.

While paddling each stroke energy is transmitted to forward momentum .

CUSTOMISATION

please check our website

DELIVERY TIME

We calculate with 6-8 weeks delivery time. In urgent needs we usually carry a choice of designs and colors on our stock for immediate delivery.

MAINTENANCE

The advantage of composites is that they don´t require much maintenance; of course there are some crucial rules to extend the lifetime of your race board:

- do not put it in the sun for long periods

- do not tight it too strongly on the rack and place it upside down

- never store or transport it inside the cover if the board is not well dry

- and treat it like a baby

USAGE

Raceboards should be used only by trained persons or under supervision

WARRANTY

we offer a 2 year warranty but do not take responsibility for:

- misuse

- damage caused by transport

- repairs made by unauthorized personnel

This warranty covers any fabrication defects on the board or parts, as well as changes in the material characteristics.

LIGHT PARADOXA 14´ UD PREPREG CARBON HOLLOW CONSTRUCTION BLACK NAKED - LIME - freight free shipment delivery time 6-8 weeks

LIGHTBOARDCORP® PARADOXA UD PREPREG CARBON HOLLOW CONSTRUCTION

14´x 21" / Volume: 270L / wetted surface*: 19.600 cm2 / optimized rockerline: 62.5 - 77.5kg

14´x 22" / Volume: 278L / wetted surface*: 19.256 cm2 / optimized rockerline: 70.0 - 85.0kg

14´x 23" / Volume: 296L / wetted surface*: 20.100 cm2 / optimized rockerline: 77.5 - 95.0kg

14´ x 25" / Volume: 322L / wetted surface*: 21.900 cm2 / optimized rockerline: 88.5 - 112.5kg

painted glossfinish 10kg / naked carbon 9kg

Simply speaking it's very stable and super fast. Usually boards are either stable or fast - that's why it it is the PARADOXA..

Take in mind you paddle as fast as with a 23" but feel comfortable like on a 25" wide board.

In comparison to the Mantra 2.0 we arranged a wider tail and gave the front part in the first 50cm a more narrow outline. The magic rocker line is based on the super fast Mantra 23.2 with slight adjustments to meet the targeted paddler weight.The center bottom has a subtle concave with edges gradually running from round to really sharp in the tail. This creates more 1st stability without sacrificing wetted surface which creates drag. The rockerline features a flat center line and straight low rocker in the last 1/3rd which makes the board a wash riding giant even in the 2nd and 3rd wave and will save energy when needed. This shape handles wind waves and chop with the all new exaggerated "Vround" front bottom and you can easily overtake small waves cutting through instead of paddling above. The dugout stance is below waterline and the most radical design available in serial production. This is possible due to the function of our drainage valve system which let´s water out but not in. This stance position creates additional stability and better leverage and power to your blade.

The sidewalls are high to prevent water entry in rougher conditions and slim enough to offer huge standing options.

The sideline is heavily tapered in the back to prevent water entry while turning.

Overall flex is super stiff, way far from what you know from premium eps core carbon boards. Our new UD - AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY in hollow construction has 4 layers of unidirectional carbon around the center high density foam layer. The curing process is accurate managed under pressure and heat in AUTOCLAVE technology.. Every stroke will push you forward and you will not loose energy in flex.

The carbon outer shell is that tight that you do not need a gelcoat or 2k lacquer for protection. So we decided you can choose the even more lightweight naked version or some variety in design and colors.

The new PREPREG UD technology is not only superior in speed but also the most ECO FRIENDLY way to manufacture - no eps core, no wet lamination and excess resin.

Cheers Gerd

AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY - eco friendly

This technology is based on premium production standards developed for aerospace and formula racing cars. 4 layers of epoxy resin impreganted unidirectional carbon fiber with a closed cell high density pvc foam in the center are layed up in the mold . There is no wet lamination necessary as the curing happens in autoclave technology using 4-5 times atmospheric pressure + heat which melts the resin and bonds all layers far more accurate compared to wet lamination process. Our new UD PREPREG technology is far more eco friendly than conventional build sup raceboards. No styrofoam core, less harmfull lamination process, no excess epoxy resin and guaranteed precision to bond each fiber leads to longevity, precise shapes and higher performance.

While paddling each stroke energy is transmitted to forward momentum .

CUSTOMISATION

please check our website

DELIVERY TIME

We calculate with 6-8 weeks delivery time. In urgent needs we usually carry a choice of designs and colors on our stock for immediate delivery.

MAINTENANCE

The advantage of composites is that they don´t require much maintenance; of course there are some crucial rules to extend the lifetime of your race board:

- do not put it in the sun for long periods

- do not tight it too strongly on the rack and place it upside down

- never store or transport it inside the cover if the board is not well dry

- and treat it like a baby

USAGE

Raceboards should be used only by trained persons or under supervision

WARRANTY

we offer a 2 year warranty but do not take responsibility for:

- misuse

- damage caused by transport

- repairs made by unauthorized personnel

This warranty covers any fabrication defects on the board or parts, as well as changes in the material characteristics.

3D PREVIEW TOOL - ZOOM & ROTATE

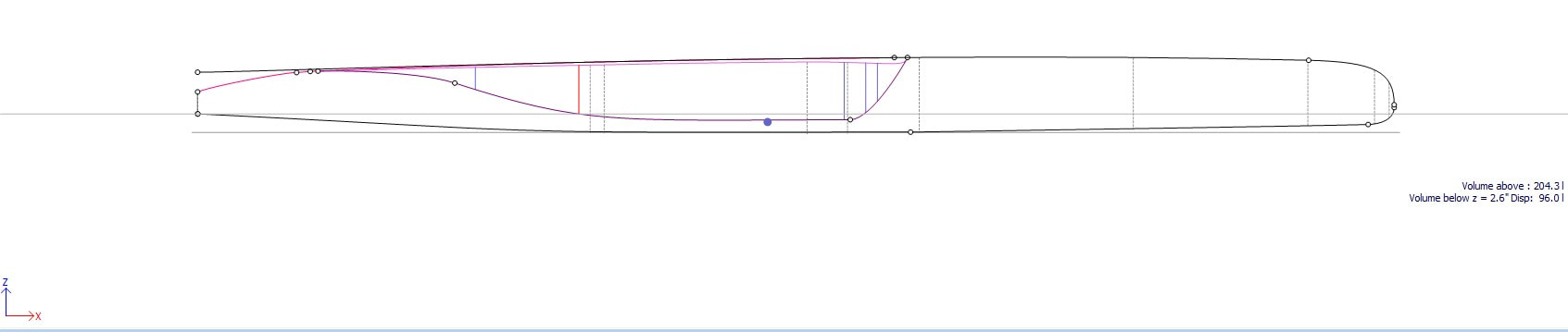

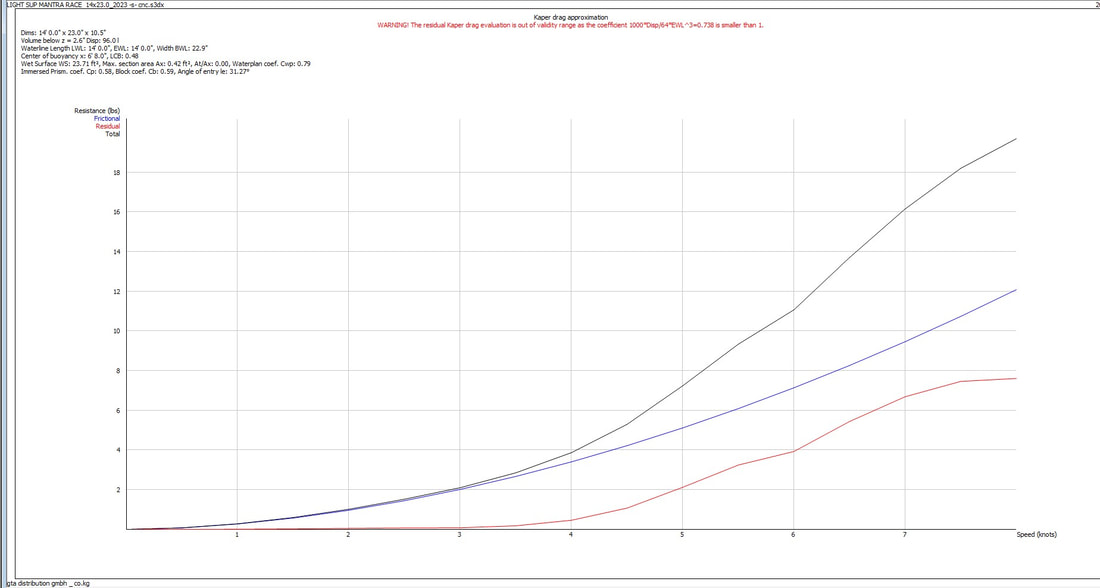

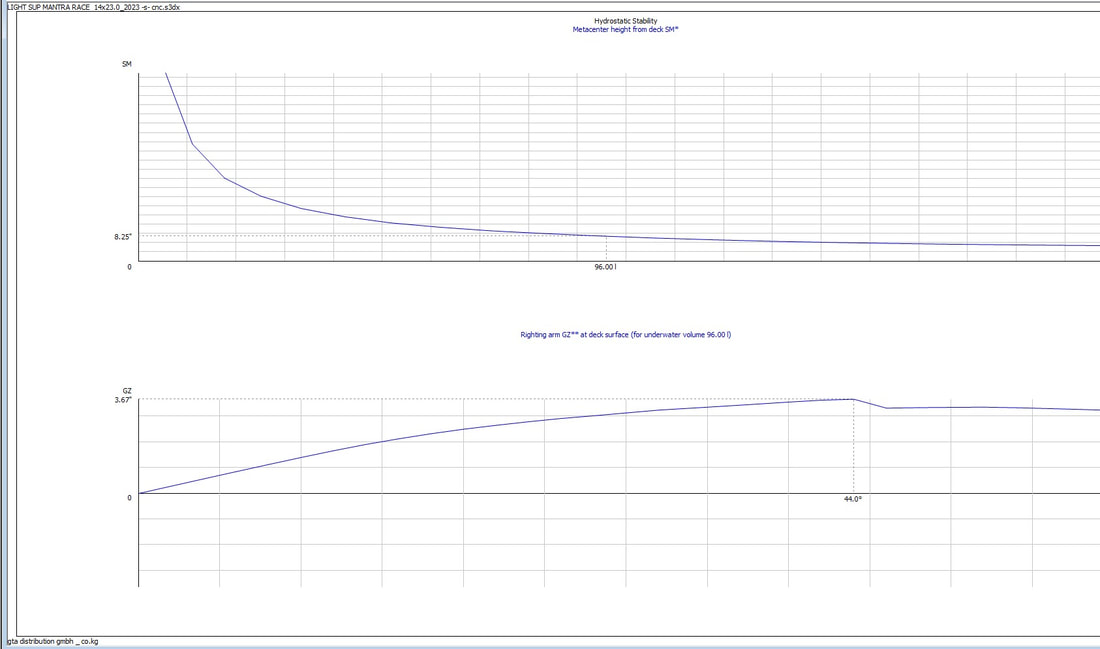

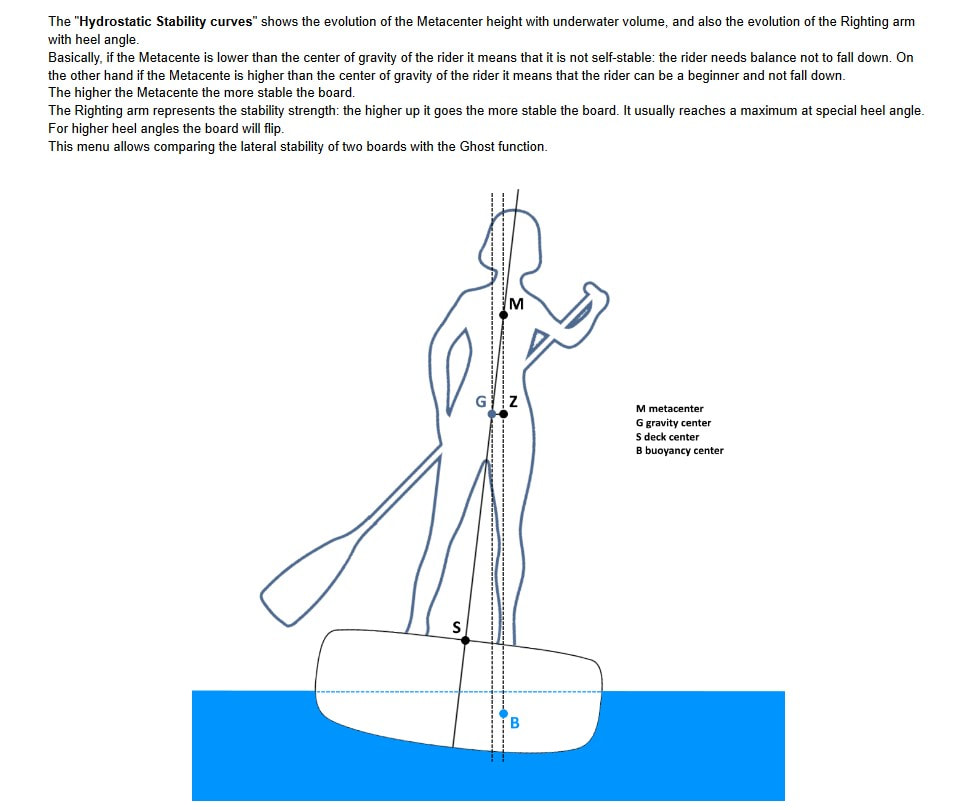

KAPER APPROXIMATION formula based on tests on sea kayaks. This curve can be far from the truth, consider it with caution. But we figured out that this measurement reflects our product development comparisons in sup as well. We see this as a usefull tool in designing the fastest sup raceboards.

Dimensions, wetted surface, outline, rail design, bottom contour, volume distribution come into play. In the design process our main target has been speed and stability. So we compared multiple design options to create stability while not sacrificing the speed potential.