|

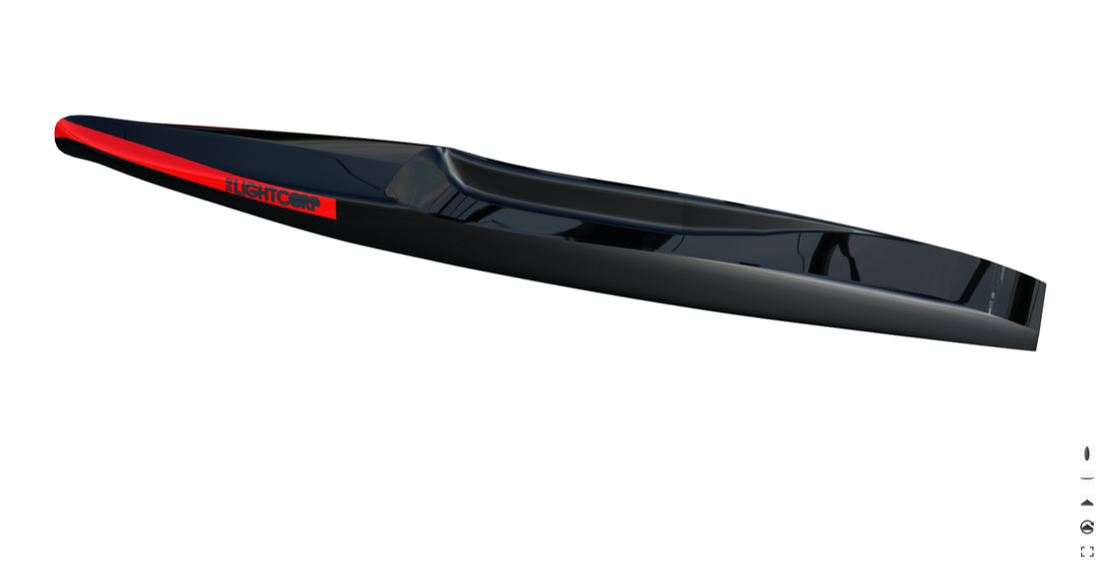

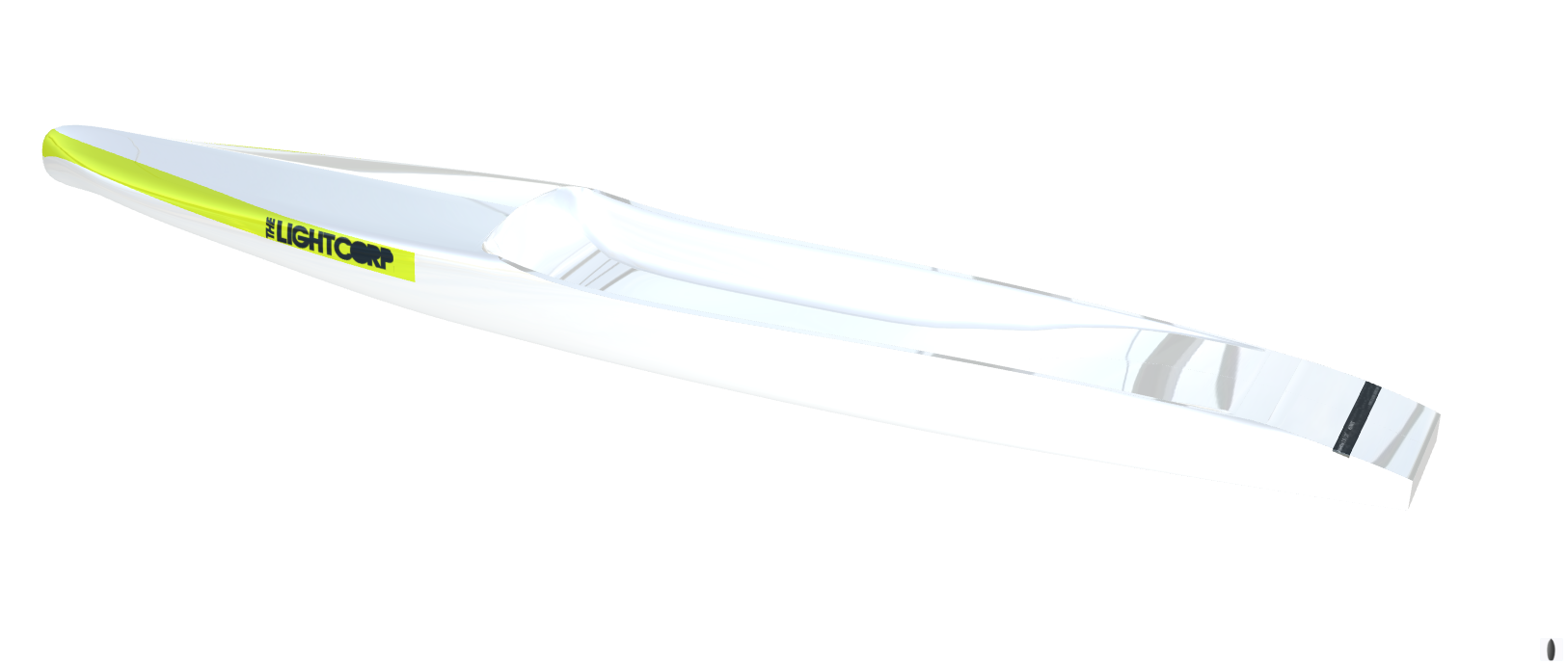

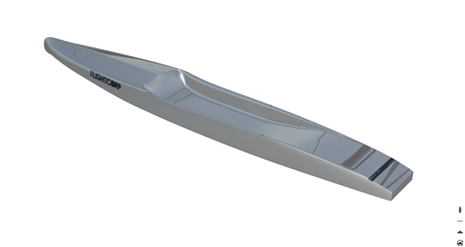

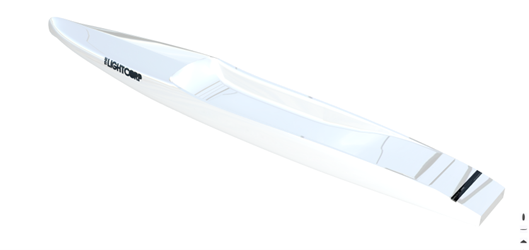

New Shape FOCUSED ON SPEED AND STABILITY

new lower center deckstance - under waterline - combined with drainage valve system new tail shape optimizing stability and easyness of turning - wider tailblock with tapered thickness 40cm of tail hard tail edges to create the least possible interference releasing the water optimized nose shape reduced drag new s-style deck contour to reduce water entry at buoy turns |

LIGHTBOARDCORP MANTRA 2.0 UD PREPREG CARBON HOLLOW CONSTRUCTION

14´x 21" / Volume: 270L / wetted surface*: 19.600 cm2 / optimized rockerline: 62.5 - 77.5kg paddler 14´x 23" / Volume: 296L / wetted surface*: 20.100 cm2 / optimized rockerline: 77.5 - 92.5kg paddler 14´ x 25" / Volume: 322L / wetted surface*: 21.900 cm2 / optimized rockerline: 88.5 - 102.5kg paddler * all shapes are cad designed and have optimized rockerlines based on assumed paddler weight and board dimensions. Waterline is exactly at the bottom tail edge with full running length to the tip of the nose. Speed potential of the boards is based on general hull shape and one key factor is the wetted surface creating drag. Simply speaking a board with deeper concaves in the bottom might be slimmer but wetted surface will be higher compared to our Mantra 2.0 . It took some time to release this new version but we innovate and then release new models once there is a real advantage. This new shape is optimized for the best flatwater performance but can handle choppy conditions: |

AUTOCLAVE UNIDIRECTIONAL CARBON PREPREG TECHNOLOGY - eco friendly

This technology is based on premium production standards developed for aerospace and formula racing cars. 4 layers of epoxy resin impreganted unidirectional carbon fiber with a closed cell high density pvc foam in the center are layed up in the mold . There is no wet lamination necessary as the curing happens in autoclave technology using 4-5 times atmospheric pressure + heat which melts the resin and bonds all layers far more accurate compared to wet lamination process. Our new UD PREPREG technology is far more eco friendly than conventional build sup raceboards. No styrofoam core, less harmfull lamination process, no excess epoxy resin and guaranteed precision to bond each fiber leads to longevity, precise shapes and higher performance.

While paddling each stroke energy is transmitted to forward momentum .

While paddling each stroke energy is transmitted to forward momentum .

|

Unidirectional Prepreg carbon fiber fabric is non-woven and features all fibers running in a single, parallel direction. It is pre impregnated with resin in a computer controlled process. There are no gaps between fibers, and each fiber is impreganted with exactly the amount of resin that is necessary for perfect bonding in the lamination process. There is no cross-section weave that divides the fiber strength in half with another direction. This allows for the concentrated density of fibers that provide maximum longitudinal strength.

|

Closed cell high density PVC foam is used for the core between the carbon layers. It provides stiffness and durability in a lightweight sandwich structure. We use different thickness layups to create extra durability in strategic areas of the board hull.

|

The composite curing AUTOCLAVE lamination process is the key factor for better durability, weight advantage and longevity. Autoclave enables us to control the cure time, temperature, pressure and vacuum accurately. The bonding between the unidirectional prepreg carbon fibers, pvc sandwich foam is leading the uncomparable strength ratio. It is aso less harmfull for the envionment and working staff as we do not need to operate in the classic wet lamination process.

|

The boards are finished with high quality 2K Marine paint providing 100% UV protection and superior scratch and chemical resistance. Our finish is usually shiny but we offer matt finish as well.

There is a clear design stripe in the tail of the boards with the visible UD construction and handwritten serial number and dimension. We offer multiple design proposals. |

3D PREVIEW TOOL - ZOOM & ROTATE

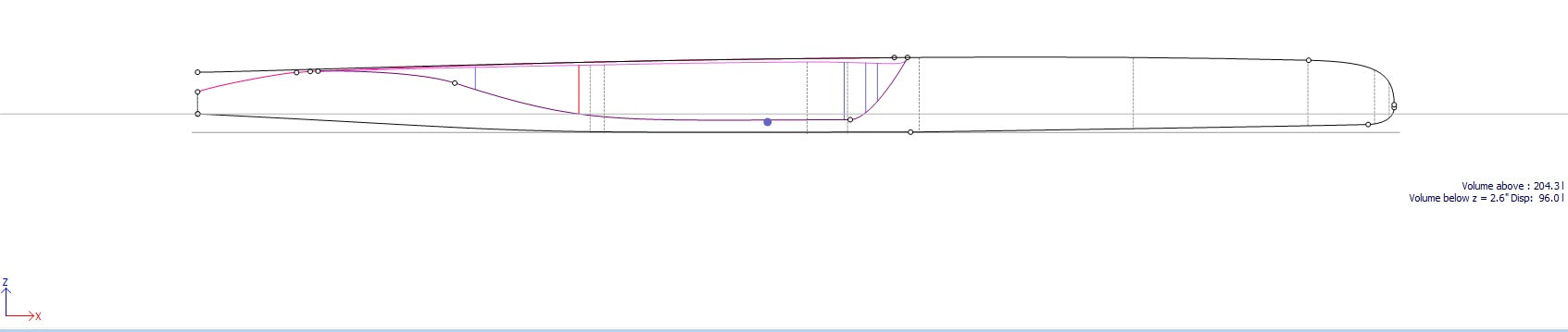

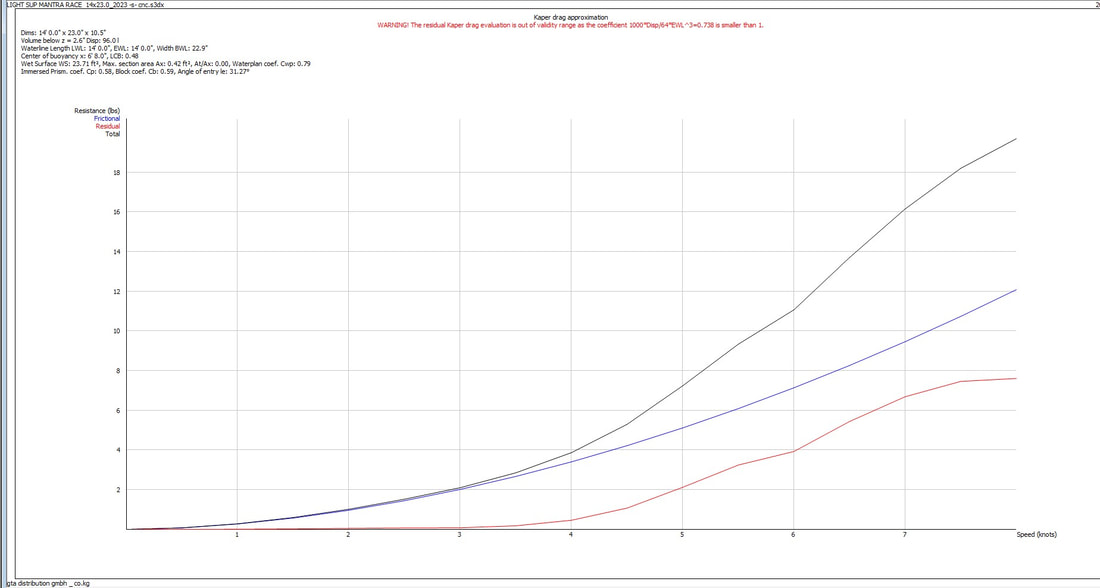

SIMULATION OF WATERLINE, FRICTION AND HYDROSTATIC STABILITY BASED ON PADDLERS WEIGHT 86kg + BOARD

The "KAPER Drag approximation" gives the evolution of the viscous drag and the residual (wave) drag with speed. The residual drag is given by the

KAPER APPROXIMATION formula based on tests on sea kayaks. This curve can be far from the truth, consider it with caution. But we figured out that this measurement reflects our product development comparisons in sup as well. We see this as a usefull tool in designing the fastest sup raceboards.

KAPER APPROXIMATION formula based on tests on sea kayaks. This curve can be far from the truth, consider it with caution. But we figured out that this measurement reflects our product development comparisons in sup as well. We see this as a usefull tool in designing the fastest sup raceboards.

HYDROSTATIC STABILITY

Dimensions, wetted surface, outline, rail design, bottom contour, volume distribution come into play. In the design process our main target has been speed and stability. So we compared multiple design options to create stability while not sacrificing the speed potential.

Dimensions, wetted surface, outline, rail design, bottom contour, volume distribution come into play. In the design process our main target has been speed and stability. So we compared multiple design options to create stability while not sacrificing the speed potential.